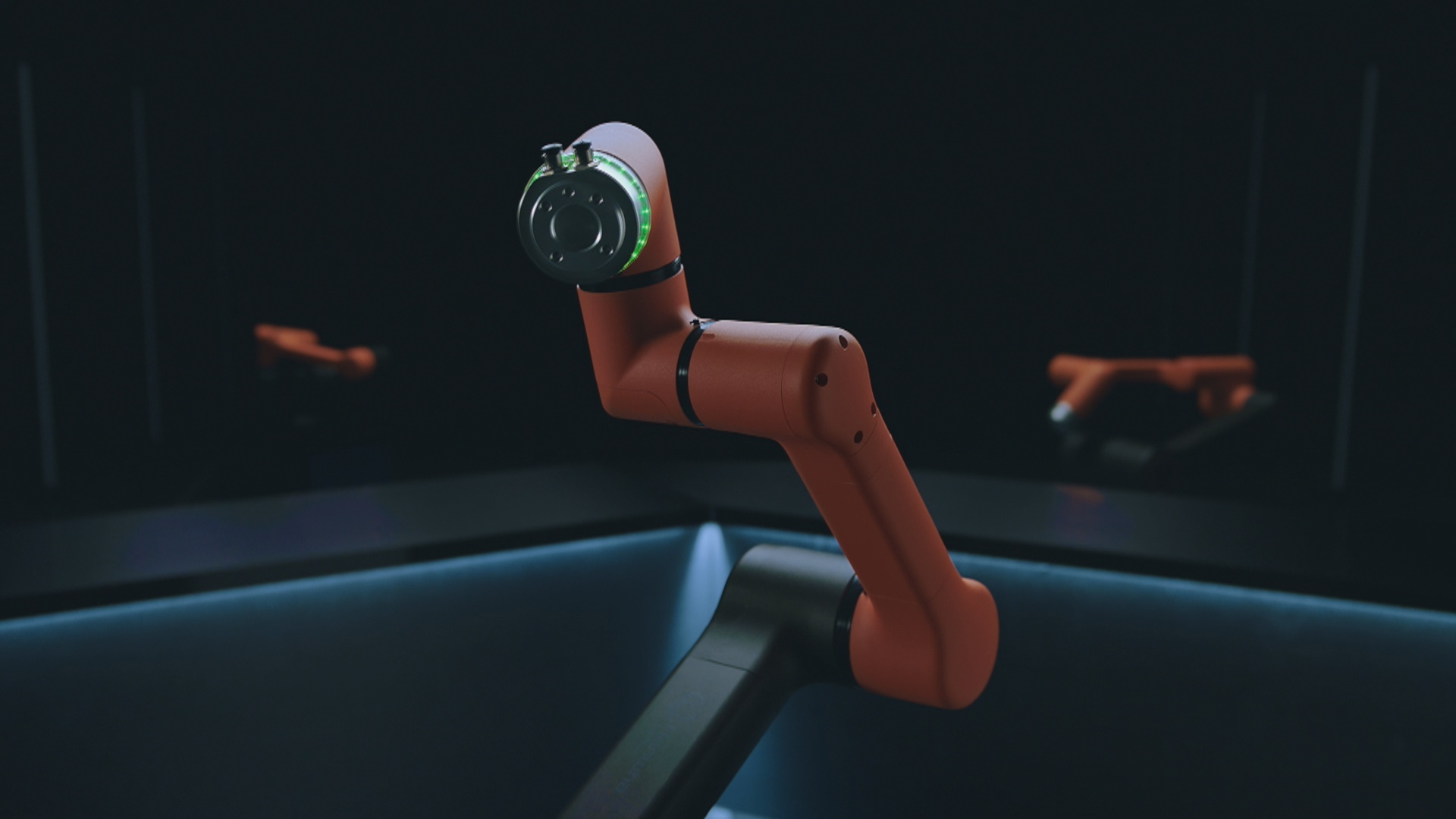

What are Cobots

Cobots, or collaborative robots, are a new generation robot and are designed to work with humans in a common workplace to complete a variety of production or storage tasks.Cobots cover a wide range of applications and can work almost anywhere in a factory as they are programmed and installed very quickly while in most cases they do not require specialized training.

Where are Cobots used

They work along with human side by side on production lines and warehouses to cover repeatedly and non-ergonomically friendly tasks in the following industries:

- Food and Beverages

- Medicines and Cosmetics

- Plastic, Chemical

- Tobacco and Tobacco Products

- Logistics

- E-Commerce

What applications do Cobots have

Cobots automate simple but also complex non-ergonomic tasks, such as:

- Auto Pick & Place

- Case Packing

- Palletizing

- E-Commerce

- Quality Control

- Assembling

- Machine Tending

Benefits from using Cobots

Flexibility

Cobots can operate almost anywhere in production or warehouse as they are suitable for a wide range of applications, while their planning and installation is extremely fast.

Ease

The installation and programming of collaborative robots is very easy, while in most cases no specialized training is required.

Security

Cobots are robots designed to work with humans in a common workplace. That is why the safety standards that accompany them are very strict, while no infrastructure is required in fences or safety bars!

Productivity increase

In addition to the benefits of automation, the coexistence of robots and humans significantly reduces the % percentage of inactivity of employees.

Return on Investment

Investing in a cobot system improves a company's competitive advantage, while return in investment is immediate, usually 1-2 years.

Cost reduction

Repeated automation and increased productivity significantly reduce costs per product produced.