CobotMat CP-11 is a Plug & Play Collaborative Palletizer that receives products directly from the production line and palletizes them according to pre-defined patterns. CobotMat is compact & versatile whilst its advanced safety features allow for safe & efficient collaboration with humans in the same working space.

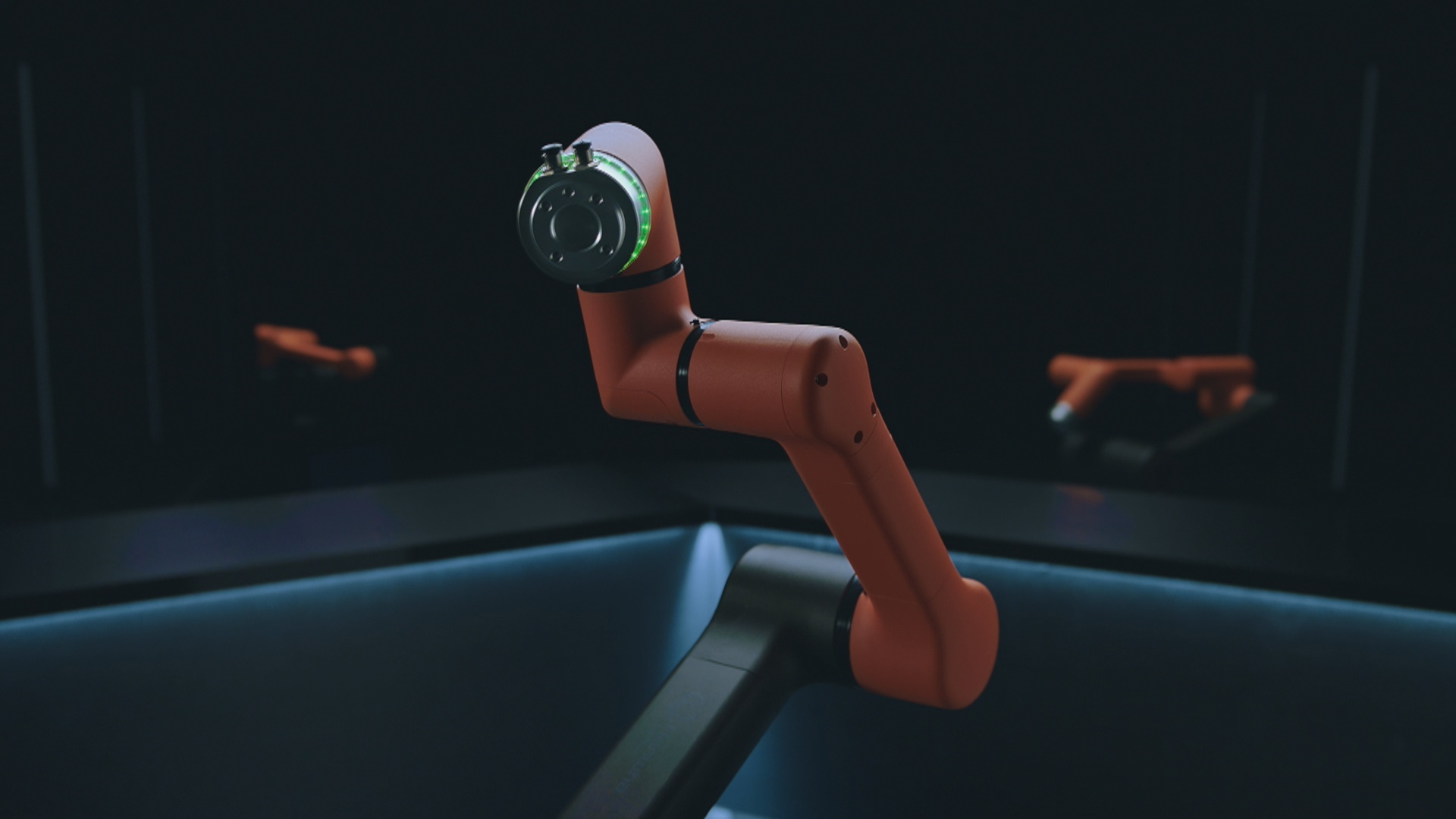

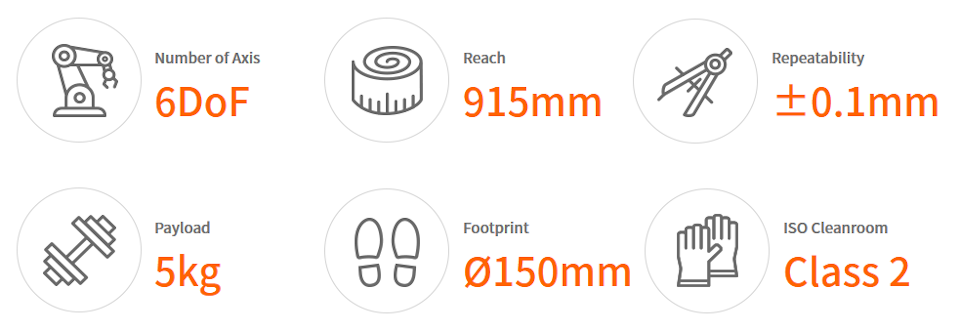

With the use of a Cobotic arm from leading Korean manufacturer HANWHA, it ensures high speed and precise product handling while its compact design makes it ideal for sites with limited available space.

The “Plug & Play” features of CobotMat make its integration to the line extremely easy. Non-specialized personnel can install, commission and even move the system to different factory lines or program new products or palletising patterns.

Due to its compact design and very fast ROI, CobotMat CP -11 is ideal for small-to-medium productions and sites with limited available space, such as Pharma, Snacks, Coffee, Plastics, etc.

An IoT ready system incorporating the latest technologies of Industry 4.0.

Benefits:

- Safety / Human Collaboration

Its advanced safety features meeting ISO 138849-1 standards allow safe & efficient collaboration with humans in the same workspace. - Fast & Easy / Flexibility / Upgradeability

It is extremely Fast & Easy to install and commission CobotMat CP-11 on existing lines. New products or patterns may be programmed very fast and the system can even be moved between lines. Moreover, the system can be upgraded to cover increased productivity, taller pallets and interlayer sheet. - Reliability / Minimum Maintenance

CobotMat Series incorporates our 30 years of engineering excellence and combines intelligent design, top quality materials and robust construction, providing increased productivity, high precision, minimum downtime and very low maintenance requirements. - Fast ROI

The return on investment for CobotMat is extremely fast making robotic automation a “no brainer” to even sites with small productions. productivity, higher pallets, interlayer sheet, etc.